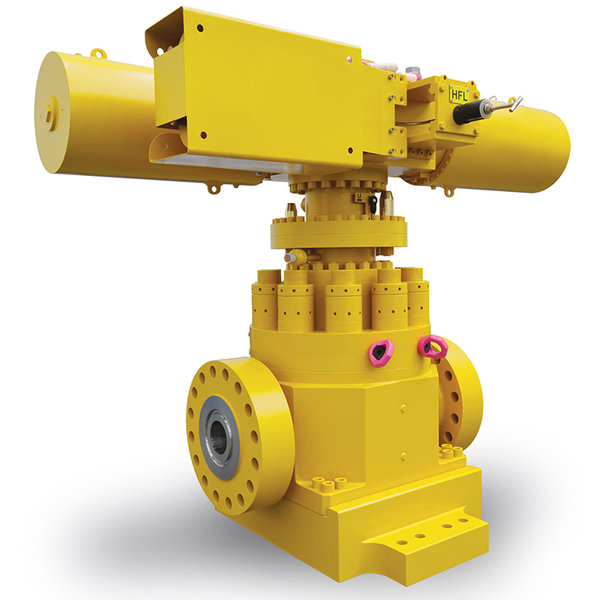

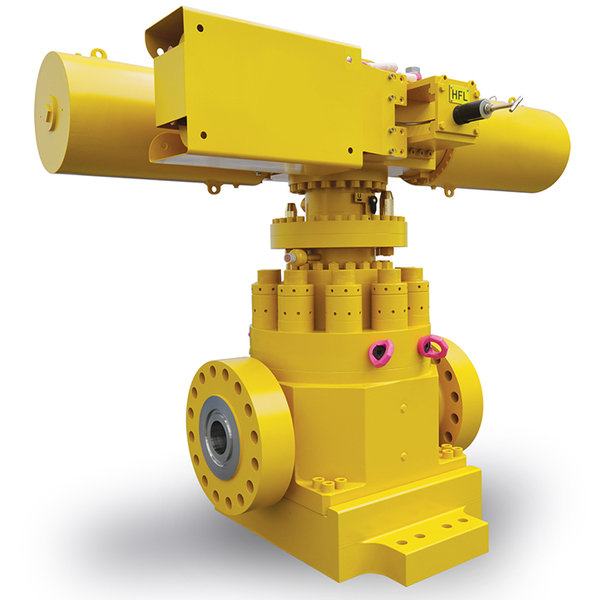

Subsea Top Entry Ball Valve

Highlights

- Suitable for high pressure and high temperature service

ATV designs and manufactures a full range of Side Entry Ball Valves, trunnion mounted, two pieces, for offshore subsea applications in the Oil & Gas exploration, production and transmission, suitable for water depths to 3000 m (10000 ft).

Top entry ball valve offers the advantage of a compact design. Typically, soft-seated configuration is available for clean service whereas metal-to-metal sealing is the preferred choice for highest reliability in harsh service with the presence of solid particles, high pressure and high temperature.

Materials are sourced from qualified suppliers on the base of specifications that reflect the industry standards (API, ASTM, BS, DIN, NORSOK or others), but do also incorporate additional requisitions resulting from long experience.

The subsea ball valves may be manually operated (by diver, if feasible) or fitted with hydraulic actuators, rack and pinion or helical spline design, with double acting or fail safe, with or without ROV override. Retrievable design is available in order to have the possibility to declutch the actuator and retrieve it to the surface or reposition it on another valve, without affecting the production line. ATV provides different proprietary design for ROV bucket or diver retrievability, while the interface for the landing tool will be made to the user’s design. ATV offers the highest level of performance and reliability being its actuators engineered to grant safe and extended operating life.

ATV designs, manufactures and tests its products in accordance with all the relevant Industry standards and codes (ANSI, API, ASME, BS, DNV, ISO, NACE, PED and others). ATV ball valves can be manufactured up to product specification level PSL 4.

ATV stresses its willingness to produce engineered ball valves; therefore it welcomes requests for special size, class and design requirements.

Images

Subsea Top Entry Ball Valve - Specifications

SPECIFICATION

| MAIN DESIGN STANDARD | API 17D / ISO 13628-4 | API 6DSS / ISO 14723 |

| APPLICATIONS | Production manifold, flowline, Pipeline End Manifold (PLEM), Pipeline End Termination (PLET), Emergency Shut Down, Subsea Isolation, HIPPS, HPHT | Subsea Pipeline, Riser, Pipeline End Manifold (PLEM), Pipeline End Termination (PLET), HIPPS |

| APPLICABLE STANDARDS | API 17D, ISO 13628-4, ASME VIII, NACE MR0175 and other diffused Industry standards | API 6DSS, ISO 14723, ASME VIII, ASME B16.34, ASME B16.10, ASME B16.5, NACE MR0175 and other diffused Industry standards |

| RANGE | 2 1/16” ÷ 9”, Class 3000 psi and 5000 psi, 1 13/16” ÷ 7 1/16” Class 10000 psi, 1 13/16” ÷ 5 1/8” Class 15000 psi, 1 13/16” ÷ 3 1/16” Class 20000 psi. Any other size upon request. | 2” ÷ 60” Class ANSI 600, 2” ÷ 48” Class ANSI 900, 2” ÷ 36” Class ANSI 1500, 2” ÷ 20” Class ANSI 2500. Larger sizes available on request. |

| WATER DEPTH | Up to 3000 m (10000 ft). Greater depth upon application. | Up to 3000 m (10000 ft). Greater depth upon application. |

MAIN FEATURES

| Forged body, one piece | ||

| Bolted Bonnet | ||

| Trunnion mounted | ||

| Full Bore | ||

| Piggable | ||

| Single Piston Effect (SPE) | ||

| Soft or Metal Seated | ||

| Wear resisting hardfacing on sealing surfaces | ||

| Qualification to PR2 | ||

| Double Block and Bleed (DBB) | ||

| Local position indicator |

END CONNECTIONS

| Flanges (to API 17D / ISO 13628-4) | ||

| Flanges (to ASME B16.5 up to 24” and B16.47A for 26” and larger) | ||

| Compact flanges (to Norsok L005) | ||

| Studded flanges | ||

| Buttwelded ends | ||

| Hub ends for clamped connections (as per customer requirement) |

MATERIALS

| Carbon steel with partial or full CRA overlay on the wetted areas | ||

| Low alloy carbon steel with partial or full CRA overlay on the wetted areas | ||

| Stainless steel | ||

| Duplex and Superduplex stainless steel | ||

| Nickel Alloy |

OPERATORS

| ROV operated gear | ||

| Quarter turn hydraulic actuator w/ or w/o ROV Override | ||

| Electric multiturn |

OPTIONS

| Reduced bore | ||

| Double Piston Effect (DPE) seats or mixed configuration (SPE/DPE) | ||

| Stem extension | ||

| ROV bucket extension | ||

| Local position indicator extension | ||

| Remote indicators (LVDTs and Limit switches) | ||

| Double Block and Bleed (DBB) | ||

| Retrievability of the actuator |